About Us

FPS Inc.

FPS Inc.

As a “Made in Japan” we have developed planar wave speakers which excel cone type spherical wave speakers (which has been regarded as common sense for over 80 years) in various properties such as sound damping rate, directivity, outreach, original sound reproduction and recycle rate.

Appreciated by these outstanding characteristics, our speakers has been used at various places such as station platforms, lecture halls and vehicle interior spaces in Japan and abroad, contributing to social security, safety, and satisfaction through utilizing the sound.

We won the Special Award in The Monodzukuri Nippon Grand Award, and we are going to develop our technologies further, prevailing planar wave speakers all over the world.

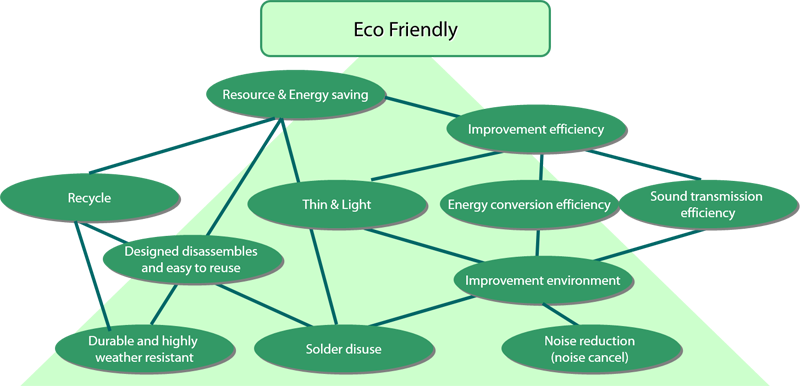

We aim for constructing a system of eco-friendly manufacturing, efficient resource usage, product collection and product revitalization. With our “eco-friendly” principle and with thinness, compactness and high efficiency as our keywords, we have been developing smaller, thinner and lighter products. Our original planar wave MCMA technology enabled revolutionary compactness and high efficiency, contributing to space, energy, and resource saving effects which were unthinkable by conventional cone speakers.

With thinness, compactness and high efficiency as our keywords, we have been developing smaller, thinner and lighter products. We need much less material than conventional cone speakers do, resulting in less carbon and greenhouse effect gas emission.

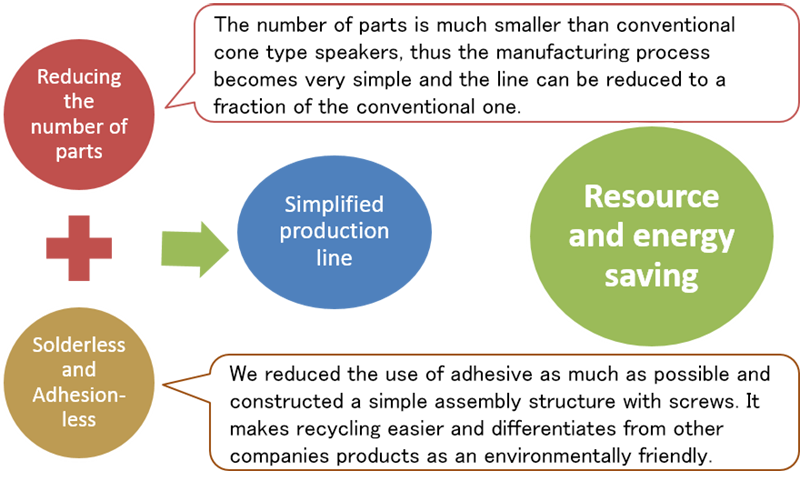

Number of main parts comparison

Cone speaker: 16-17

FPS flat speaker: 4-6

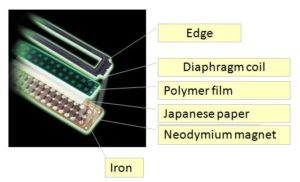

All our magnets for products are neodymium magnets. Ferrite magnets, used in conventional cone speakers, are difficult to recycle because they gradually lose magnetic power by use, and because they are fragile and easy to break especially in removing. On the contrary, neodymium magnets are stronger in magnetic power and coercive force, easily removable because they lose magnetic power with 140 degrees heat for 10 minutes, and recyclable with 99% of first magnetic power if you apply voltage again.

◆ Unification of diaphragm coil and polymer film through evaporation coating

◆ Unification of diaphragm coil and polymer film through evaporation coatingOur diaphragms adopt polymer films attached voice coils through evaporation coat, due to enhancing production recycle rates. Thus we can easily dissolve membrane films and coils when we recycle.

Our products that from units to large speakers, use screws, which make easy to dissolve. For example, you can dissolve parts from our station speakers, because we are assembling it by screws, without using adhesives.

FPS flat panel speakers maximize energy efficiency as speaker. Due to material strength such as magnet, diaphragm and polymer film, as well as original air damper structure, our speakers have 30% higher electricity-audio conversion efficiency than conventional cone speakers, leading to less greenhouse effect gas emission.

Our challenges for recycling start from designing for small and efficient products requiring less resource. We achieve 99.5% (weight base) recycle rate by easy-to-dissolve and reuse designing from materials for magnet and diaphragm to adhesive-free and soldering-free structures.

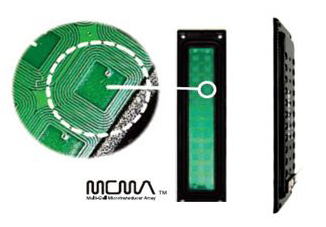

We're (FPS Inc.) manufacturing & selling the thin Flat Panel speakers that generate planar wave technology by our original development MCMA.

MCMA:

It is a general term for flat panel speakers’ latest model uniquely developed by FPS company. On the polymer vibrating membrane there are many microcells which will function as speakers, and, in parallel, with the diaphragm’s piston moving, it will work as a surface sound source, not point sound source.

It has a crystal clear sounds loved by peoples who has a broad range of ages.

We developed the Nanofibers production machine that high-performance sound absorption and heat insulation (product name "SELAB Nano (R)"). We are manufacturing and sales the Machine to the Nanotechnology market. Nanofibers are searching and studying these years as Dreamy material. But, there are health problems that manufacturing processing, and it was difficult to mass-production due to its cost bigger expensive. Our new technology develops succeeded to resolve these problems. Easy to use by anyone, and we are sure to contribute various fields.